High Speed Press Roller feeder

Roller Feeder Advantages:

* Productivity: can be multi-engineering continuous processing

* High speed: up to 600 times per minute

* Versatility: Regardless of the width and thickness of the material, simply adjust the feeder to match the mold can be used.

* Simple structure, economical and practical, low failure rate, easy maintenance.

Feeding accuracy:

* Depending on the number of revolutions and the length of the feed, the accuracy is 0.05mm. If the guide tip for positioning, the more ± 0.01mm accuracy.

Type:

* Single type: apply to the coil (thickness 0.15mm or more), single or continuous punching products used.

* Duplex: suitable for the coil (thickness 0.15mm below), short foot material, single product or continuous punching products used.

The four major features of the structure:

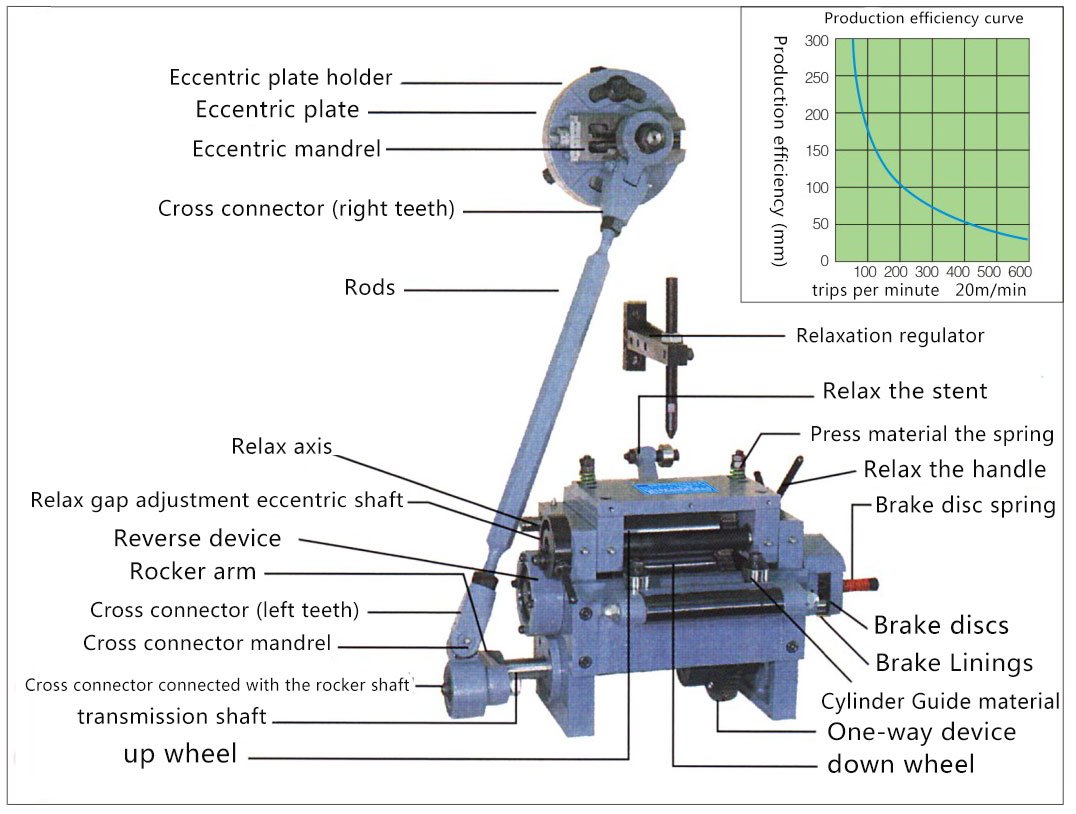

1, one-way bearing

1.1, embedded with superhard alloy, and with roller bearings, with wear resistance, stability, high precision, long life.

1.2, gear after heat treatment HRC60o and then precision grinding, high precision transmission.

2, wheel

2.1, the use of hollow, light weight, rotation inertia is small, can immediately stop to ensure that feeding accuracy.

2.2, heat treatment HRC60o chrome and then grinding, high hardness, excellent wear resistance, long life.

3, disc brakes (general brake device)

3.1 using advanced clutch to make the rain surface completely contact, long life, good stability, high precision.

4, reverse device

4.1, construction and one-way device, can be quite precise control of the next round, long time will not make the next round of the slightest retrogression, stability and accuracy is quite high.

4.2, not because of the splashing of the residual oil, leaving the brake lost recorded the next round of reverse, the distance is not allowed to pass the phenomenon.

4.3, not easy to produce high fever.

4.4, with a hard alloy and roller, easy to wear.

4.5, the action for the roller for circular motion, rather than as a guide pillar 4 linear movement, so there will be no bite the phenomenon.

4.6, the friction is small, the required transmission torque is relatively reduced, the transmission mechanism is less likely to damage.

4.7, if the reverse device equipped with the speed of up to 30 m / min, usually 20 m / min, an increase of 50% efficiency.

4.8, special structure, increased service life.

Note: Each model, the general brake device are equipped with standard parts.

If the machine has another reverse device, the general brake device for the auxiliary, that is, double brake system.