Materials that can be used for high-speed punching presses?

What is high speed precision automatic punching machine? That is to say, it is a kind of punching machine family, which is made of integrated special cast iron alloy, high rigidity and strong anti-vibration. High-speed punching machine has advanced and easy control system, high precision, high speed and high stability. Next, I will explain what fields the high-speed punching machine can be applied to and what materials can be used for high-speed punching press?

What are the products that can be stamped by high-speed punching machine?

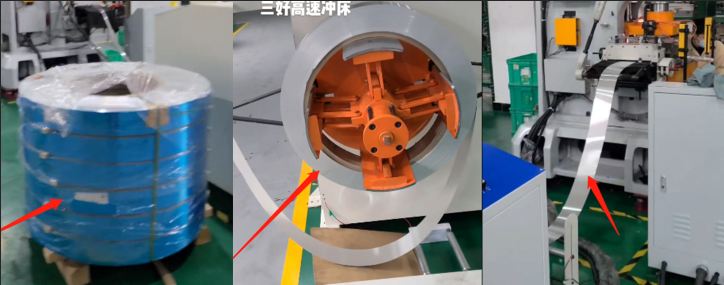

The products that can be stamped by Samhoor high-speed precision punching machine are as follows.

Copper pipe heat sink High speed stamping machine

Precision terminal hardware parts

Various connector stamping

Various sizes of mesh stamping

Various types of heat sink stamping

Stainless Steel Cable Tie Production Line

Various kinds of led bracket stamping on lamps

All kinds of metal lead frame stamping

Various servo motor stator stamping

Electronic Connector High Speed Press Machine

Various kinds of stainless steel tie stamping

Textile machinery reed tooth

Anti-intrusion razor barbed wire, etc.

Materials which're suitable for high-speed press stamping:

The stamping material is an important factor affecting the quality of the parts and the life of the die. Currently, the materials available for stamping are not only mild steel, but also stainless steel, carbon tool steel, electrical silicon steel, aluminum and aluminum alloys, brass, bronze and copper alloys, etc. Note that due to the very high speed of the high-speed press, for safety and efficiency, the stamping material must be in strips or coils in order to be suitable for automatic feeding in continuous high volume production. Some of the commonly used stamping materials are described below.

1. Hot-rolled steel

Hot rolled steel is a kind of high-quality carbon structural mesh with carbon content of about 0.10%-0.15%, which is low carbon steel. There are three kinds of hot rolled steel commonly used in stamping: SPHC, SPHD and SPHE. Among them, SPHC is the most representative steel of hot rolled steel; SPHD has stronger tensile property than SPHC; and SPHE has better tensile property than SPHC.

2. Cold Rolled Steel

Cold rolled steel is also a kind of high-quality carbon structural steel, with carbon content of 0.08%-0.12%, which is low carbon steel. There are three kinds of cold-rolled steel commonly used for stamping: SPCC, SPCD and SPCE, among which SPCE and SPCD have better tensile properties than SPCC.

3. Stainless steel

Stainless steel is a high alloy steel with chromium content of 11% or more, which has strong corrosion resistance and heat resistance, and has stainless and surface brilliance.

4. Copper and copper alloy

Copper and copper alloys have non-magnetic function, do not produce pickling phenomenon at low temperature, corrosion resistance, good cutting performance, beautiful color, is one of the common metal materials for stamping.

5. Aluminum and aluminum alloy

Aluminum and aluminum alloy materials can be divided into two categories according to their manufacturing and forming processes: extension materials and casting materials. Heat-treated alloys are heat-treated by quenching and aging treatment to obtain the required strength. Aluminum has the advantages of beautiful appearance, excellent processability, corrosion resistance, electrical conductivity, low temperature characteristics, good overall performance and recyclability.

Quality requirements of materials for high-speed press stamping:

The material quality requirements for stamping with high-speed punching machines include the following:

1. The surface of the material must be smooth and flat, free of scratches, pores and shrinkage.

2. There is no delamination in the cross section of the material and no obvious mechanical property damage.

3. The surface of the material is free of rust spots, oxidation skin and other adhesions.

In the process of high-speed stamping, the material with good surface quality can obtain a smooth surface and high-quality work. And it is not easy to break during the deformation process and not easy to damage the die. In summary, the requirements for the surface of the product in the stamping process of high-speed punching machine are still relatively high.

Types of high-speed punching machines:

There are two types of high-speed punching machines, namely C-type high-speed punching machines and gantry high-speed punching machines. So what are the differences and advantages between them both? For more details, please check the news on the homepage for more exciting contents.

Samhoor Company

Samhoor's Chinese transliteration: three advantages,Expressed as: good quality, good price, good service.This is the request of Samhoor High Speed Press,But also the purpose of customer service.

Industry News

Contact Us

- No. 10, Dakeng Road, Juqi Community, Humen Town, Dongguan, Guangdong, China

- +86 15916804664

- server@samhoor.com