How to maintain the stamping dies of high-speed power press machine?

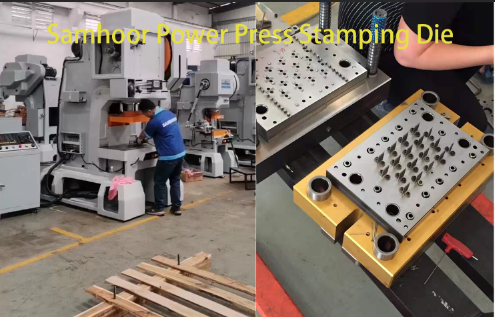

In the power press industry, I believe someone in the industry knows that high speed punching machine is a kind of stamping type press, through which punching dies can make various metal stamping parts products such as drop, punching and forming, and many precision parts can be made through the dies of punching machine. In the last issue, we introduced how to install the press die safely and easily on the high-speed punching machine? In this issue, I will introduce to you how should we maintain power stamping dies of high-speed punching machine?

The service life of high-speed punching press dies depends on reasonable die structure, high manufacturing accuracy, good heat treatment effect and correct selection of punching machine, precision of stamping and stretching parts installation, etc. Besides, the correct use, maintenance and repair of dies is also a link that cannot be ignored.

Then how should we do the maintenance of high-speed punching press dies?

First-level maintenance of stamping dies:

I. Maintenance during die installation

1. Before die installation, clean the upper and lower surfaces of the die to ensure that the die mounting surface and the press table are not damaged by compression and that the upper and lower mounting surfaces of the die are parallel in production.

2. After installing the die, open the die, clean and wipe all parts of the die, especially the guiding mechanism. Clean the surface of the mold to ensure the quality of the parts and lubricate the sliding parts of the mold with grease. Check all parts of the mold, especially the safety side pins, safety screws, side plates, punching waste channels and other safety parts.

II. The maintenance in production

1. In production, the parts used in the mold need to be oiled regularly, the parts including the compression ring of the stretching die, the rounded corners, the edge of the cutting- edge die, etc. should be well oiled and lubricated.

2. The small hole scraps of the trimming die hole need to be cleaned regularly.

3. Drawing die convex die, concave die, in the maintenance, the rounded corner of the die pulling part is mainly polished, if there is a pressure pit, the die should be repaired.

III. Post-maintenance

1. After the use of the equipment is finished, the moulds need to be inspected.

2. To clean the mold thoroughly to ensure the cleanliness of the mold.

3. Cleaning up the waste in the mold to make sure there is no waste in the waste bin.

4. Observing in real time how the die is used and after use.

Secondary maintenance of stamping dies:

1. Ensure the best die clearance. The die clearance is the sum of the gap between the two sides as the punch enters the lower die. Different plate thicknesses and materials should be selected with different gaps in the lower die in order to reduce burrs and collapse, keep the plate material flat, prevent banding problems, ensure good punching quality and prolong the service life of the punching die.

2.Timely sharpening effectively prolongs the service life of stamping dies. When the edge of the die wears to produce an arc with a radius of about 0.1mm, it should be sharpened in time. When sharpening, grind 0.03~0.05mm each time and repeat until the punch is sharp. After sharpening, polish the edge with an oil stone to remove the burrs and apply lubricant after magnetic treatment.

3. Checking the alignment of the upper and lower die holders of the turntable regularly, if the die position of the punch press is not well aligned, it will speed up the speed of die dulling and the processing quality will become poor.

4. Checking and lubricate the die holes and guide keys on the turntable, if there is any damage, they should be repaired in time; check the wear of the keyway and replace it if necessary; use special mandrels to calibrate the die position, if there is any deviation, adjust it in time.

5. Cleaning the upper and lower die holders of the turntable so that the lower die can be installed accurately.

6. When punching soft or sticky materials such as aluminum, punching thin abrasive materials such as glass epoxy sheet, punching thin hard materials such as stainless steel, frequent and continuous punching can make the surface harden, adopt titanium plating, nitriding and other methods to make the surface harden layer thickness of 12~60um of molecular structure of the punch.

7. Guide parts (guide pillar, guide bush, guide plate, etc.)

Guide parts such as pull marks are mainly due to unclean lubricating oil and guide gap deviations, guide parts produce pull marks, which are eliminated by polishing methods after being pushed in with oil stones.

8. Springs and other elastic parts

Spring in the process of use, is easy to damage parts in the mold, usually broken and deformation. If these conditions occur, we should replace the spring, but when replacing it, we need to pay attention to the specification and type of the spring. The specification and model of the spring is determined by the color, outer diameter and length, and the spring needs to be replaced only if these three conditions are the same.

9. Plunger chip and blunt set

Most of the plunger chip and punches blunt set used in the mold are standard parts. In the process of using the mold, the punches are easily broken, bent and gnawed, and the punches and punches are usually gnawed, and the damage to the punches and punches is usually replaced by parts of the same specification.

10. Fastening parts

Fasteners need to be checked frequently to see if they are loose and damaged, and if so, find parts of the same specification for replacement.

The above is the maintenance knowledge of high-speed stamping machine stamping dies shared by Joey, have you learned it?

About how to install the stamping die of high-speed power press machine safely and easily, please turn to the previous article introduction, thank you for your supporting.

Samhoor Company

Samhoor's Chinese transliteration: three advantages,Expressed as: good quality, good price, good service.This is the request of Samhoor High Speed Press,But also the purpose of customer service.

Industry News

Contact Us

- No. 10, Dakeng Road, Juqi Community, Humen Town, Dongguan, Guangdong, China

- +86 15916804664

- server@samhoor.com