High-speed punch and high-speed mold in detail

High-speed punch and high-speed mold in detail

High-speed presses and high-speed molds are the difference in accuracy, the difference between the accuracy of the price is naturally different. Good horse with a good saddle, used in high-speed molds and high-speed punch is also applicable.

Punch difference: ordinary punch bed structure is simple, lack of rigidity, table parallelism is poor. More with a single punch or mold products are not high precision mold. Ordinary price is estimated to be thousands of dollars cheaper.

The high-speed punch bed bed structure is complex, honest, rigid feet, table parallelism 0.005MM, is more high-end punch, parallel degree 0.02MM, slightly worse, the price is also hundreds of thousands. Most of the imports of Japanese punch in more than one million, Switzerland has more than 200 million, the accuracy is not a little bit of the problem.

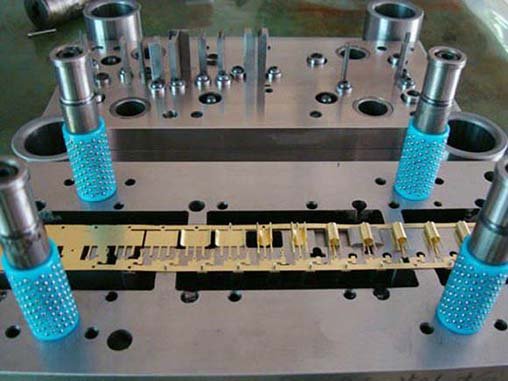

The most important part of the high-speed mold is the guide post, and its guiding accuracy determines whether the mold parts are accurate. Ordinary punch mold general product accuracy is not high, so the precision mold parts will be much lower, the guide parts will naturally be reduced, such as the guide column, the use of a circular guide and round guide sleeve, are round with, but belong to the gap With the specifications, according to different specifications of the unilateral gap in the 0.01mm-0.03mm; and high-speed punch mold, the product is relatively high precision, relatively large, long production cycle, in order to facilitate the maintenance of precision mold to naturally improve a lot, The precision of the mold-oriented part of the internal guide column and the outer guide post, the current high-speed punching inside and outside the guide pillars are guide pillars, guide sets, with the ball sets of the way, with the The gap is a rolling interference fit, the upper and lower mold parts accuracy and position can be controlled at 0.002-0.005mm, processed stamping parts accuracy can be guaranteed in the + -0.01 to + -0.02.

Different molds: different materials, ordinary mold even with our common ordinary steel, precision high-speed molds currently use the majority of imported SKD11 material, in addition, the precision of mold processing thickness control difference is large, precision mold board requirements control in the 0.002 -0.005mm parallelism and flatness, the ordinary can reach 0.02mm is very good. Heat treatment is also different, precision molds are commonly used in cryogenic treatment, or even ultra-deep cold treatment, in order to eliminate the processing stress so that the template is more stable without deformation.

Parts of the processing and different materials, ordinary parts and more use of fast wire processing, precision plus or minus 0.02, roughness; precision parts of the use of walking wire processing accuracy plus or minus 0.005 or less, material, precision mold parts for more durable, The use of tungsten steel as a part, its life will increase several times.

Precision mold with a sophisticated punch drive will show the advantages of precision molds: fast, good stability, high precision, easy maintenance. The current high-speed common in 1000 times / min, the product of different mold size and production speed will be different, more than 200 rush common.

Samhoor Company

Samhoor's Chinese transliteration: three advantages,Expressed as: good quality, good price, good service.This is the request of Samhoor High Speed Press,But also the purpose of customer service.

Industry News

Contact Us

- No. 10, Dakeng Road, Juqi Community, Humen Town, Dongguan, Guangdong, China

- +86 15916804664

- server@samhoor.com